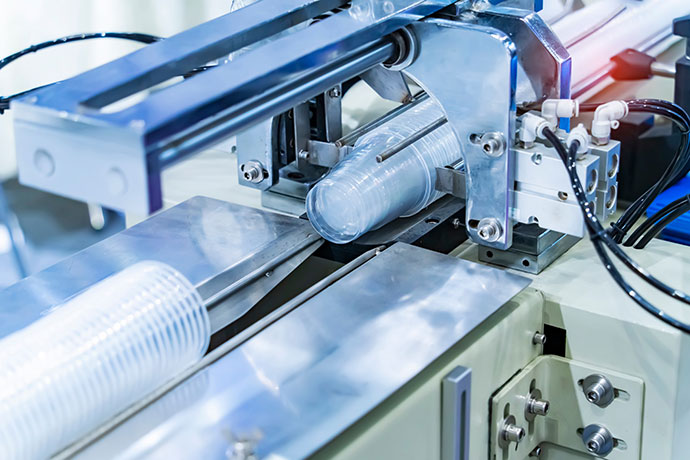

We schedule prototype and service runs for any machine. Usually 1-2 week turnaround for parts off your existing tool. If you need tooling, submit a request and we will get a quote with Blue Water Tooling for full service prototyping.

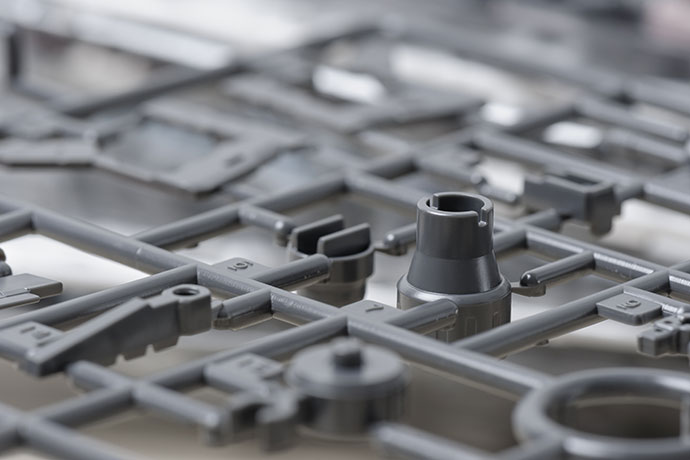

Prototype injection molding is used across various industries due to its ability to produce precise, functional prototypes quickly. Some common applications include:

When you work with Blue Water Molding, you get the benefits of our outstanding and innovative molding operations: